It’s an exciting time to be part of the construction industry. With commercial buildings being one of the major sources of carbon emissions in the U.S., many architects, designers and engineers have taken up the challenge to create greener, more energy-efficient alternatives to widely-used materials.

Some innovators improve on existing formulas and processes in the development of office buildings. Others aim to replace non-recyclable materials, eliminate the harmful volatile organic compounds released by industrial adhesives or use the versatility of smart materials that can adapt their properties to changing external stimuli. Keep reading to find out more about some of the most exciting innovations that are shaping the office of tomorrow.

Biodegradable, Self-Assembling Mushroom-Based Materials

When we envision the office of tomorrow, we rarely think of nature as playing a key role in shaping the look and functionality of the workspace. Perhaps we should, as recent discoveries about the properties of fungi have given us the means to address some of our most challenging sustainability issues.

As mushrooms digest nutrients externally, scientists observed that enzymes released by certain varieties during this process can break the chemical bonds between plastic molecules, potentially leading to a solution to our global plastic waste problem. The 2018 State of the World’s Fungi report by the Royal Botanic Gardens highlights possible mushroom-based replacements for polystyrene foam, leather and other materials with a high carbon footprint.

Based in Green Island, N.Y., Ecovative Design is focused on creating biodegradable packaging, storage solutions and patented biomaterials by harnessing the structure of mushroom mycelia. The mycelium is the fungus’ vegetative part, made up of branching roots. This self-assembling network provides structure and acts as a biological binder for hemp agricultural waste. In its Mycelium Foundry, Ecovative can create smart materials by varying the texture, porosity, fiber orientation, resilience, and strength of these root-like structures which can then be incorporated into items like Gunlocke’s Savor chair or London-based designer Niri Meri’s mushroom lamps, replacing chemical glues, resins, and other non-degradable components. The resulting material uses no formaldehyde and contains no harmful volatile organic compounds (VOCs).

Aerogels Provide Better Insulation

Mayor Bill de Blasio recently declared that New York City is “going to introduce legislation to ban the glass and steel skyscrapers that have contributed so much to global warming,” turning a spotlight on some of the objections raised about current sustainability standards for new developments. Office buildings account for a significant amount of global carbon emissions, and even LEED-certified properties have a lot to improve in terms of energy efficiency.

A lot of power goes into regulating the temperature inside these buildings but improving thermal resistance through better insulation is essential to keep operating costs down and reduce energy waste. Made by removing liquid from gels, aerogels are the world’s lightest solid material, containing up to 99% air. The highly porous material provides excellent thermal, acoustic and electrical insulation, while also saving precious space due to its relative thinness compared to conventional insulation.

Aspen Aerogels developed Pyrogel, a silica-based aerogel, re-enforced with a non-woven carbon and glassfibre batting. It is a highly flexible material with an extremely low thermal conductivity, ideal for insulating curved and complex surfaces. Pyrogel is hydrophobic but allows vapor to pass, which reduces steam formation and condensation. This versatile insulation can be applied to internal or external walls, rooftops, terraces, ceilings, windows and even ducts and pipework.

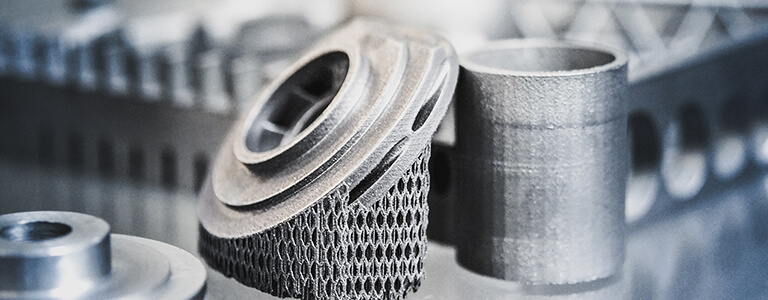

3D-Printable Steel

Steel has allowed buildings to soar without having to sacrifice space and light due to the previously used method of thick load-bearing masonry walls for multiple storied structures. To this day, it is one of the safest, most affordable and readily available solutions for developers looking for durability and strength. It’s recyclability also renders it a key component of energy-efficient and low-carbon or carbon-neutral buildings.

Researchers at the Idaho National Laboratory developed NanoSteel. By changing the ratios of components like chromium and manganese in the conventional steel alloy, the process led to the formation of a smaller crystal structure. These new nanostructures alter the material’s mechanical and physical properties, improving its overall performance.

Steel is also one of the metals suited for 3D printing, an ideal method for creating intricate shapes with half of energy used in traditional manufacturing, and a 90% reduction in wasted material. NanoSteel’s latest research focuses on BLDRmetal L-40, an alloy powder that can be printed at room temperature on commercial equipment to create tools and gears.

Source: Shutterstock

Eco-Friendly Concrete

Widely used in construction, cement production accounts for roughly 6% of global CO2 emissions and is inordinately harmful to the environment. Watershed Materials addressed this issue by developing the Watershed Block, a proprietary geopolymer mix which requires 65% less energy to produce than conventional concrete masonry.

The material contains no cement, fly ash, blast furnace slag, or metakaolin. Since it doesn’t require any of the byproducts of burning coal or iron and steel production, the Watershed Block can be produced globally using any local clay-based minerals. As this type of masonry contains no colorants or dyes and relies instead on locally sourced minerals. The varying geologic origins provide a custom look to each batch of blocks and helps the resulting buildings seamlessly fit the regional palette.

The Napa-based company’s designs exhibit remarkable resistance to water and chemical erosion and have demonstrated compression strengths as high as 7000psi, twice the strength of ordinary concrete.

Thanks to its reliance on widely available and recyclable components and because its manufacturing does not require high temperature kilning, curing, or proximity to any industrial site for access to quarry or steel forging byproducts, mass production of the Watershed Block would be a sustainable alternative to conventional masonry.

Seeing the Future Through Smart Glass

In their effort to build more energy-efficient buildings, office developers are experimenting with innovative technologies. Smart materials are designed materials that have one or more properties which can react to chemical, electrical, magnetic, mechanic, or light stimuli.

View, a Milpitas, Calif.-based company, incorporates one such material in their Dynamic Glass. Intense sunlight triggers an electrical charge within the smart glass which makes ions move between multiple thin layers of metal oxide, causing the windows to darken. The darker the glass, the more radiation and glare are rejected, creating a comfortable environment for those inside, reducing eyestrain, drowsiness and improving productivity.

A sky sensor in the Dynamic Glass detects whether incoming clouds are likely to alter the lighting conditions and adjusts the tint accordingly. According to its website, View’s Dynamic Glass lowers energy consumption by 20% and blocks 99% of UV radiation.

Notable projects in the company’s portfolio include installations at San Francisco International Airport, and Boston Logan International Airport, as well as work done for clients like Delta Lines, Kaiser Permanente, FedEx and Wells Fargo.

Source: Shutterstock

Fiber-Based Composite Panels

ECOR Global produces a high-performance, sustainable green building material that aims to provide an alternative for traditional materials such as wood, MDF, cardboard and foam. ECOR is an environmental composite panel created by applying heat and pressure to various fibers, from old corrugated cardboard, to newsprint, agricultural fiber, office and forest waste. The resulting material doesn’t splinter and outperforms its competitors in terms of strength to weight ratio.

ECOR can be used for everything from office partitions, to architectural elements, store displays, furniture or emergency shelters. The material is available in several colors and treatments to enhance fire, moisture and acoustic performance can be applied.

Whole Foods Décor Designer, Paul Geary, worked with ECOR Global to create VOC-free ceiling fixtures and signs in four San Diego and Orange County locations.